OBJECTIVE

At the end of the course the participants will be able to set up designs for formulations and to analyse the experimental results.

INTENDED AUDIENCE & PRIOR KNOWLEDGE

Participants in this course are expected to have completed DOE-I. The target audience is equal to those for DOE-I: R&D in chemistry, chemical and biological pharmacy, plastics processing, paint industry.

SET-UP

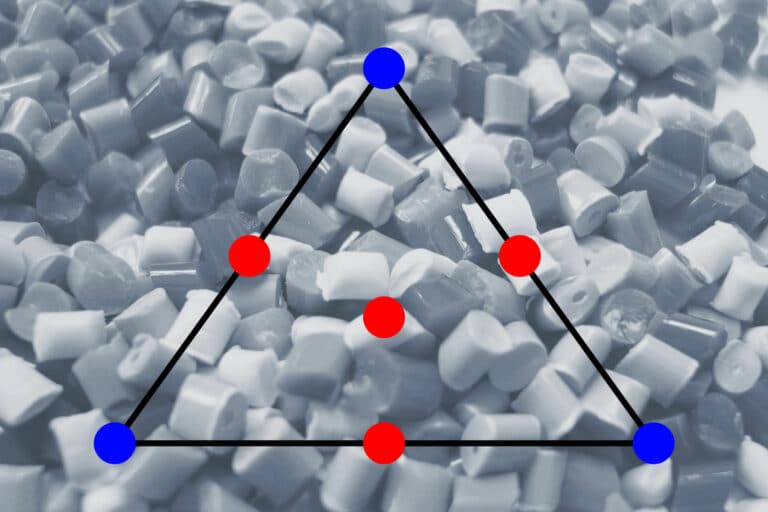

This course deals with the specific design problem of studying formulations like polymer blends, drugs, paints, coatings, cosmetics. Although the basic principles are the same, designs, models and their interpretation are different from those for “ordinary” problems. The training also covers D-optimal as they will often be the only solution to formulation problems. Theory will be illustrated with hands-on exercises.

CONTENTS

- Formulations – an introduction

- Designs for regular design regions

- Scheffé models

- Analysis, interpretation and visualisation of mixture models

- Designs for irregular design regions (optimal designs)

- Irregular regions: Response Surface Modelling

- Mixture-process problems

CASES & APPLICATIONS

- To arrive at a recipe for paint that is easy to apply, has sufficient coverage, hardens quickly and is UV resistant.

- Choose the composition of a tablet so that it remains whole in its packaging, passes the stomach, but then easily disintegrates.

- Make a blend of those types of polymer, each with a dozen candidates, to make a plastic with the right impact strength, flexibility and being coatable.

- Optimizing a process for reactive extrusion, where the polymer blend as well as the reagent and the extruder settings must be selected.