OBJECTIVE

The goal of this course: to offer a thorough introduction to SQC, with emphasis on typical situations in the process industry: one-at-a-time sampling, short-run processes, batch processes, serial correlations (“drifts”) and complex measurements.

INTENDED AUDIENCE AND PRIOR KNOWLEDGE

Participants are expected to be familiar with the material covered in the course ‘Statistics in Practice (SIP)’. No prior knowledge of SQC is required.

The course is aimed at people who work in the process industry, be it chemical or pharmaceutical, biological or purely physical. Whether you are responsible for the production process, quality control or a specific laboratory analysis, you will be able to immediately apply in your work what you learned in this course.

SET-UP

In this course theoretical aspects are alternated with hands-on exercises. All examples and exercises are based on chemical processes.

CONTENTS

Standard SQC

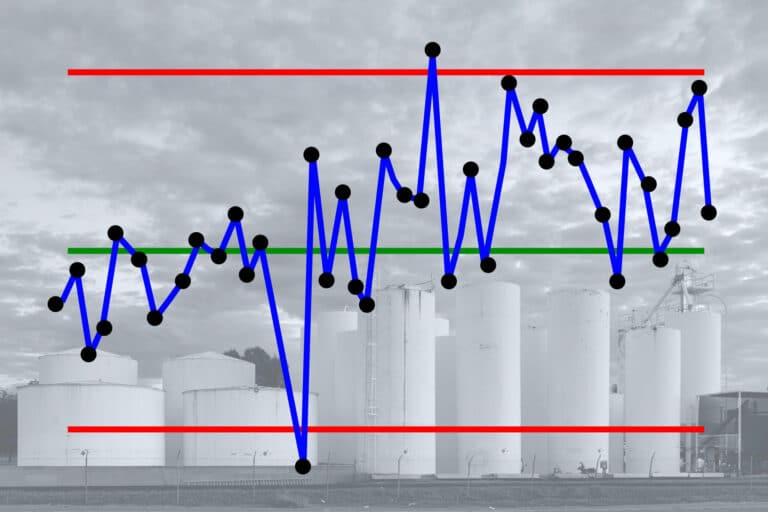

- Basic principles of control charts

- Traditional control charts: X, X-bar, R, S, S2, MR2, p, np, c and u

- Moving Average (MA) chart

- Exponentially Weighted MA (EWMA) chart

- Cumulative Sum (CUSUM) charts

- Process Capability Analysis: meaningful measures

SQC for the lab and measurement systems

- %R&r / Measurement Capability / Precision to Tolerance

- Identification of Variance Components: R&r study

- Monitoring measurements and the lab

SQC in process industry – specific solutions

- Control charts for ‘short-run’ processes and ‘between-within batch’ charts

- Serial correlation: detection and remedy

- SQC in an Automatically Regulated Process

CASES & APPLICATIONS

- deliver consistent quality in production

- guaranteeing the reliability of a laboratory analysis

- determine which factors critically influence an analysis result

- monitoring the number of incidents per month

- projects of quality improvement of a product